The Challenge: Inefficient Inventory and Lost Sales

ElectroSmart, a rapidly growing retailer of consumer electronics with both online and brick-and-mortar stores, was facing significant challenges with its inventory management. Their existing manual processes led to:

- Stockouts: Popular items frequently went out of stock, resulting in lost sales and customer dissatisfaction.

- Overstocking: Conversely, slow-moving items accumulated in warehouses, tying up capital and increasing storage costs.

- Inaccurate Forecasting: Difficulty in predicting demand fluctuations led to inefficient purchasing decisions.

- Time-Consuming Audits: Manual inventory audits were labor-intensive and prone to errors.

These inefficiencies were hindering ElectroSmart's growth and impacting its profitability. They recognized the need for a more intelligent and automated solution.

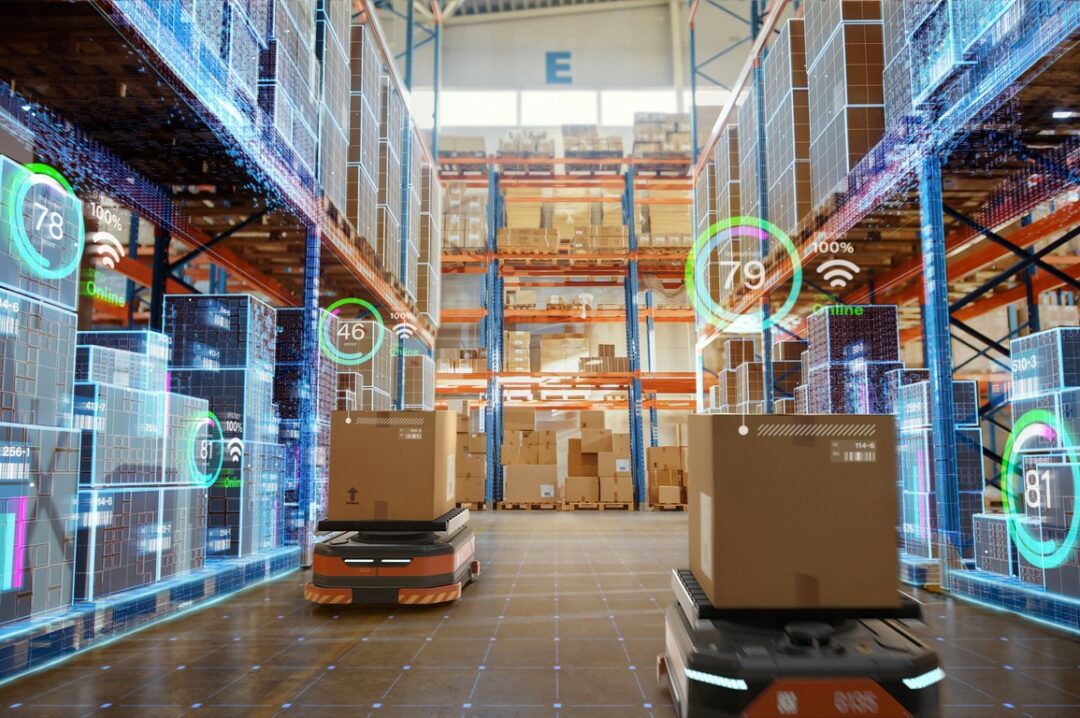

The Solution: Implementing an AI-Powered Inventory Management System

To address these challenges, ElectroSmart partnered with [Your Company Name/Our Solution Name] to implement a custom AI-powered inventory management system. The solution leveraged:

- Machine Learning Algorithms: To analyze historical sales data, seasonal trends, marketing campaigns, and external factors (e.g., economic indicators) to generate highly accurate demand forecasts.

- Real-time Inventory Tracking: Integration with their point-of-sale (POS) systems and warehouse management systems (WMS) provided a live view of inventory levels across all locations.

- Automated Reorder Points: The system automatically calculated optimal reorder points for each product based on predicted demand and lead times, triggering alerts when stock levels fell below the threshold.

- Predictive Analytics for Slow-Moving Items: AI algorithms identified slow-moving inventory, enabling proactive strategies for discounts or targeted promotions to reduce carrying costs.

- Mobile Inventory Auditing: A mobile application with barcode scanning capabilities streamlined the inventory audit process, improving accuracy and reducing the time required.

The Results: Significant Improvements Across the Board

The implementation of the AI-powered inventory management system yielded significant positive results for ElectroSmart:

- Reduced Stockouts by 35%: More accurate demand forecasting ensured that popular items were consistently in stock, leading to increased sales and improved customer satisfaction.

- Decreased Overstocking by 20%: Intelligent purchasing recommendations based on predicted demand minimized the accumulation of excess inventory, freeing up capital.

- Improved Forecasting Accuracy by 90%: The AI algorithms provided significantly more accurate demand predictions compared to their previous manual methods.

- Reduced Inventory Audit Time by 60%: The mobile auditing application streamlined the process, allowing for more frequent and accurate inventory checks with less labor.

- Increased Overall Profitability by 15%: The combined effect of reduced losses from stockouts, lower carrying costs from overstocking, and optimized purchasing decisions directly contributed to a significant increase in ElectroSmart's profitability.